STEEL DEVISION

MARKING MACHINE

Introduction Of Item

MARKING MACHINE OVERVIEW

The production line is being diversified, including steel plate, coil, slab, billet, section steel, pipe and other construction materials. Due to the automation and rationalization of logistics, their marking works are applied with automated marking system, and not the manual work. For this, mechanical devices that are suitable for the respective markings on the target materials as well as paints/inks are being prepared in our total marking solution befitting the automated logistics.

MARKING MACHINE FEATURES

| NO | Mechanical Structure | Dedicated TYPE | A/S Easy SPACE Easy to buy Domestic |

|---|---|---|---|

| 1 | PAINT used | Available for domestic | COST DOWN effect |

| 2 | NOZZLE form | Circulating CLEANING High Temperature Type | High temperature and durability |

| 3 | MARKING HEAD structure | LM GUIDE&BALL | Fine durability and reproducibility |

| 4 | Device for sensing the target surface for marking | Mechanical TOUCH | AIR CYLINDER&indirect BAR contact method for high temperature use |

| 5 | Control system | PLC direct control | Operation and Ease of A/S |

| 6 | Character type DOT type | DOT type CHARACTER system | Sharp and consistent character type (characters do not spread or flow) |

| 7 | Localization of production capacity and facility maintenance and A/S Plan | Localize the equipment | Ability to design, manufacture, install, commissioning, A/S, MAINTENANCE |

| 8 | MARKING M/C Major Facility Procurement Plan | Urgent procurement is available | Since the third-party products are not made in Korea, we need some time to secure the product |

| 9 | Delivery results and market share | POSCO to supply localized products to major steel makers | POSCO high-temperature material MAKING MACHINE uses 100% of its products |

MARKING MACHINE TYPE

MARKING MACHINE CONFIGURATION

1. MARKING Main body

– MARKING HEAD

– Mobile equipment (normal, transverse, vertical)

– proximity S/W etc.

DESCALING DEVICE

High

-pressure injection and mechanical impact method

2. PAINT feeder

– TANK

– PUMP

– STIRRING DEVICE

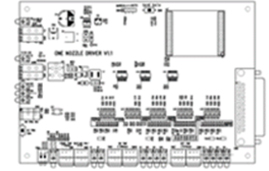

3. Device control panel

– Device manual control PANEL

4. control panel

– Built-in control device such as PLC

– Connect with parent COMPUTER

– Built-in MMI

THE MARKING SYSTEM APPLICATIONS

Mark on top

Mark on side

Mark inside

Mark on coil

NOZZLE&NOZZLE CONTROLLER

The marking nozzle is moved along with the character type by the X-Y stage mounted with Servo System. For a certain distance moved, the nozzle is controlled to spray the paint. Therefore, narrowing the injection time interval will make continuous line characters. Otherwise, dot characters are created.

- Since one nozzle forms a character on the XY axis, you can input arbitrary size, arbitrary pattern character, and mark

- It is easy to apply Character Recognition System because character type setting and change can be done through monitor screen.

- * Marking of small characters is also possible. 20 mm (H) x 15 mm (W)

- Due to the use of atomized (atomize) method, paint consumption in the hot material are less than they are in other methods.

- Target materials can control the paint being consumed according to the temperature information and mark characters with consistent thickness.

- Target materials can control the paint being consumed according to the temperature information and mark characters with consistent thickness.

1 NOZZLE MARKING MACHINE

A method in which 1 marking nozzle is mounted onto the X-Y Stage established with Servo System to mark desired characters

(including special characters) and logos.

| Marking material | Slabs, blooms, billets, heavy plate material, HR coil | |

|---|---|---|

| Standard Stage | Type A | X axis 600mm x Y axis 200mm |

| Type B | X axis 600mm x Y axis 200mm | |

| Type C | X axis 600mm x Y axis 200mm | |

| Type D | X axis 600mm x Y axis 200mm | |

| Character size | Character height More than 20mm random size | |

| Marking speed | 0.7sec/character(H=30mm P=30mm) | |

| Character thickness | 3mm or more | |

| Nozzle Distance | 3mm to 5mm | |

| Temperature of material being marked | Room temperature to 1100 ℃ | |

| Paint | Water Paint | |

| Tank Volume | 50L(standard) | |

| Data Configuration Type | Manual Settings and Automatic Linkage Settings | |

| Power | AC200V/220V or 440V 50/60 Hz | |

| Compression Pressure | 400kPa (4kgf/㎠) or more | |

| Descaling Number | 150~300L/minfat 1.5 to 2.0Mpa(15~20kgf/㎠) | |

| Washing water | 100 to 200kPa(1~2kgf/㎠) | |

NOZZLE MARKING FIELD

7 NOZZLE MARKING MACHINE

By moving 7 nozzles that are arranged in a row parallel to the target, a predetermined 7x5 matrix are filled with

characters of dots by dispersing the paint.

| Marking material | Slabs, blooms, billets, heavy plate, HR coil | |

|---|---|---|

| Character size | Height (H) | 55mm or more |

| Width (W) | 40mm or more | |

| Pitch (P) | 47mm or more | |

| Dot diameter | Φ8mm or more | |

| Types of Characters | A to Z alphabetic characters | |

| 0 to 9 digits | ||

| Other Special Characters | ||

| Marking speed | 2 to 5 characters per second | |

| Number of characters And Number of lines | Free choice | |

| Marking Of material Temperature | Room temperature to 1100 ℃ | |

| Paint | Water paint | |

| Power | AC200V/220V or 440V 50/60 Hz | |

| Compressed air pressure | 400kPa (4kgf/㎠) or more | |

| Descaling Number | 150 to 300 L/minfat 1.5 to 2.0 Mpa (15 to 20kgf/㎠) | |

| Washing water | 2 to 3 L/min (at 0.1 to 0.2 MPa (1 to 2 kgf/㎠)) | |

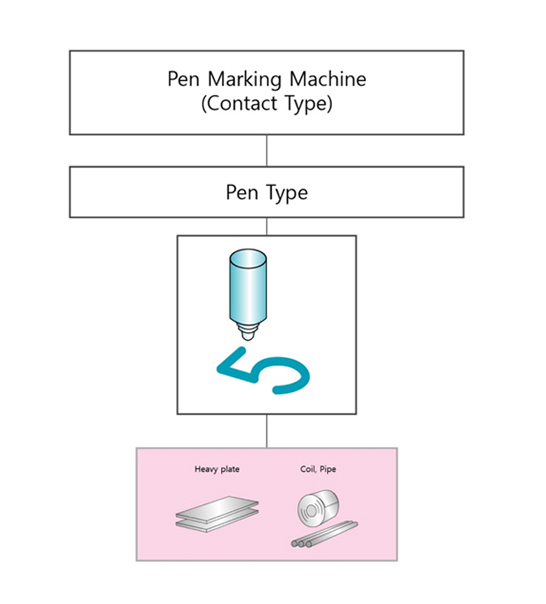

PEN MARKING MACHINE

A Felt Pen is automatically provided with the amount of ink required.

At the same time, the writing part is moved along X-Y-Z axes to form the characters.

| Marking material | Heavy plate, CR COil |

|---|---|

| Character size | Width of 30mm or more |

| Height of 400mm or more | |

| Pitch of 35mm or more | |

| Types of Characters | A to Z alphabetic characters |

| 0 to 9 digits | |

| Other special characters | |

| Marking speed | 1 character within 1 second |

| Number of characters and number of lines | Free choice |

| Temperature of Marking Subject | Room temperature to 250 ℃ |

| Paint | Oil-based ink |

SIDE COLOR MARKER (NON CONTACT TYPE)

An apparatus for marking color and product number (barcode) on the side of the heavy plate.

| Color Marking | Target material thickness of 50mm or less |

|---|---|

| Color/White, Yellow, Red (Standard) | |

| etc. Color (special) | |

| Side marking | Character height: 0.7-18.2mm |

| Font Size: In 5 dot, up to 2 24 dots | |

| Marking speed of up to 5.5mm/s | |

| Character creation method | INK JET NOZZLE |

| Temperature of marking material | Room temperature to 350℃ |

LASER MARKING MACHINE

Laser System Process

1. Waiting for home position

2. Coil distance measurement

3. Moving laser header

4. Start marking coil information

5. Completed coil information marking

6. Character recognition and verification

MARKING TAG(1-NOZZLE MARKING&TAG TYPE)

| Content | 1-Nozzle | |

|---|---|---|

| Model Type | Sad | Bloom |

| System | 1 Marking nozzle is mounted onto the X-Y Stage established with the Servo System to mark desired numbers and characters. Label printers are used to print out the product information including numbers, characters, logo and QR-CODE, and to settle the label onto the product using a gas-induced tool. | |

| Equipment Characteristics | * Marking quality is excellent. * Little Maintenance is required. * No time limit. * Character size and marking position are unlimited. *The QR-CODE helps confirm product information. |

|

| Components | *Marking&Tagmachine (Advancing, Traveling, Nozzleassembly, Detector, Gasgun) *UnitPanel *Discaler(Mechnical,water) *PLC Panel, Local Panel, HMIunit *Unit Printer |

|

| Paint Used | Domestic water-based paint | |

| Marking Speed | 1 second per character H=30mm P=30mm | |

| Character Size | H 20 mm or more random size | |

| Character Thickness | 3mm or more (±1mm) | |

| Material Temperature | Room temperature to 1100 °C | |

| Label Size | horizontal 100mm, vertical 70mm | |

| Gas Gun Pin Base Material/Length | Steel/14mm | |

| Printer Method/Mode | Printing with high-temperature ribbon/label cutting mode | |

| Operating Condition (compressed air) | 0.4 MPa (4 Kgf/cm³) | |

| Marking&Tag Status |  |

|